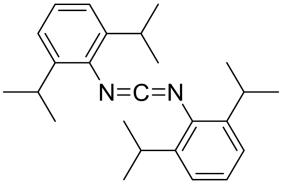

N,N'-Bis(2,6-diisopropylphenyl)carbodiimide ; nylon anti hydrolysis agent ; CAS: 2162-74-5

Main application: High-purity carbodiimide anti-hydrolysis stabilizer products, which react with hydrolysis products such as carboxylic acids or water to prevent autocatalytic hydrolysis degradation and extend the service life of many polymers.

Appearance: White or off-white crystalline powder

Melting point: 49-51℃

Purity: ≥ 99.0%(GC)

Loss on drying: ≤0.5%

Packaging: 25KG cardboard drums

Storage: The product should be stored in a cool, dry and well-ventilated indoor area, protected from direct sunlight, rain or heavy pressure. No special safety measures are required when in use. Just follow good industrial operation norms.

Application method: Material type and recommended addition amount

PET, nylon: 0.5-1.5%

PU, TPU: 0.7-1.5%

EVA: 3.5%

High-purity carbodiimide anti-hydrolysis stabilizer products react with hydrolysis products such as carboxylic acids or water to prevent self-catalytic hydrolysis degradation, thereby extending the service life of many polymers. Especially under harsh usage conditions such as high temperature, humidity, and acidic or alkaline environments, their resistance to hydrolysis and anti-aging performance are significantly enhanced. In addition to serving as an anti-hydrolysis stabilizer, it can also be used as a processing aid. It reacts with the acidic substances produced during the extrusion process to prevent the molecular weight of the polymer from decreasing during processing, thereby reducing the damage to the polymer caused by the processing. It is mainly used as a stabilizer for dry polyester products (such as PET, PBT and TPEE, etc.), polyurethane products (such as PU systems, MD prepolymers, TPU, adhesives, etc.), polyamide nylon products and anti-hydrolysis stabilizers for easily hydrolyzed plastics like EVA.